Tours

Friday 16th June 2023

The programme for euspen‘s 23rd International Conference & Exhibition in Copenhagen will include optional technical tour visits. These tours will provide delegates with the ideal opportunity to learn more about the companies facilities, capabilities, technologies, product developments and expertise.

Company Tours will take place on Friday 16th June 2023 and will run simultaneously so delegates will only be able to attend one tour.

Tour 1: DTU Civil and Mechanical Engineering

Location: Technical University of Denmark, Department of Civil and Mechanical Engineering, DTU building 427, Kgs. Lyngby, DK-2800, DK

Date: Friday 16th June 2023

Time: 09:00- 14:00

The Technical University of Denmark (DTU) is recognized internationally as a leading university in the areas of the technical and the natural sciences, renowned for our business-oriented approach, our focus on sustainability, and our amazing study environment.

The Section for Manufacturing Engineering of the Department of Civil and Manufacturing Engineering (DTU Construct) performs theoretical, numerical, and experimental research in the field of manufacturing engineering. It covers a wide range of manufacturing processes and modelling approaches, metrology at all scales, micro/nano manufacturing, and additive manufacturing. The research objective of this Section is to promote precision manufacturing to meet performance, durability, reliability, size, and cost requirements of modern products. Precision manufacturing is characterised by parts with tight tolerances and specific functional properties, often made in advanced materials with taylored properties.

CASMAT, the DTU Construct Villum Center for Advanced Structural and Material Testing provides facilities that support experimental research in the mechanics of structures and materials across all length-scales, so-called multi-scale testing ranging from micro-scale to full- and large-scale testing.

DTU Skylab, DTU’s Innovation Hub, is where the convergence of technologies and talent from different fields, combined with an entrepreneurial mindset, creates a unique culture of learning and innovation for everyone involved in our community.

DTU Nanolab is the National Centre for Nanofabrication and Characterization in Denmark. The center is an open access research infrastructure facility owned by and located at the Technical University of Denmark (DTU). DTU Nanolab pushes the boundaries of micro/nano fabrication and electron beam based characterization. With state-of-the-art infrastructure, it provides technology and education within micro- and nanofabrication and nanocharacterization and enable the industry to exploit the existing and future benefits of nanotechnology.

Tour Programme

| Time | Programme |

| 09:00 – 09:15 | DTU Construct – Welcome and Department presentation (Prof. Hans N. Hasen) |

| 09:15 – 09:30 | DTU Construct – Precision Moulding (Dr. Yang Zhang) |

| 09:30 – 10:00 | DTU Construct – Precision Machining (Assoc. Prof. Giuliano Bissacco) |

| 10:00 – 10:30 | DTU Construct – Open Additive Manufacturing and Powder Technology (Prof. Dorte Juul Jensen, Dr. David Bue Pedersen, Dr. Venkata Karthik Nadimpalli, Dr. Tianbo Yu) |

| 10:30 – 10:45 | DTU Construct – Soft Tooling Technology (Dr. Yang Zhang) |

| 10:45 – 11:30 | DTU SkyLab – DTU Incubator and Innovation Hub (Jane Pedersen, Innovation Partner) |

| 11:30 – 12:15 | DTU NanoLab – Micro and Nanofabrication (Prof. Rafael Taboryski) |

| 12:15 – 13:30 | Lunch at DTU Faculty Club – DTU building 101 |

| 13:30 – 14:00 | DTU Construct – CASMAT Large & Light Structures Mechanical Testing Lab (Prof. Christian Berggreen) |

Tour 2: Danish Fundamental Metrology (DFM)

Location: DFM A/S, Kogle Alle 5, 2970 Hørsholm, DK

Date: Friday 16th June 2023

Time: 09:30 – 12:30

Danish Fundamental Metrology (DFM) is Denmark’s National Metrology Institute (NMI), which provides a wide range of measurement services to the industry. Measurement competences are developed through research in collaboration with academia, industry and foreign national metrology institutes. Moreover, DFM disseminates metrology knowledge to companies and authorities through teaching and consulting. As an NMI, DFM specializes in measurements and calibrations traceable to the SI (Système International d’Unités) in fields such as length, mass, electrochemistry, acoustics, photonics, temperature, and time & frequency.

Website: www.dfm.dk

Coach transport to and from the Danish Fundamental Metrology Institute will be provided. The draft tour itinerary is as follows:

| Time (Approx.) | Programme (Introductory Presentations) |

| 09:30 – 09:40 | Welcome Presentation by Michael Kjær, DFM CEO |

| 09:40 – 09:50 | Length traceability at the nanoscale by Dr. Jørgen Garnæs |

| 09:50 – 10:00 | Particle diameter and particle certified reference materials by Dr. Jørgen Garnæs |

| 10:00 – 10:10 | Nanoelectrical characterization of energy- and quantum materials by Dr. Aslan Hüsnü |

| 10:10 – 10:20 | Surface cleanability by Dr. Aslan Hüsnü |

| 10:20 – 10:30 | Scatterometry – optical length measurements below the diffraction limit by Dr. Astrid T. Rømer |

Laboratory Tours

The laboratory tours will be split into 5 groups of 10. If less than 50 people attend, the group numbers will remain with reduced group sizes.

| Duration | Programme |

| 10 Mins | Scatterometry lab. |

| 10 Mins | Particle lab. |

| 20 Mins | Mass lab. |

| 20 Mins | Length lab. |

| 20 Mins | Nanoprep. lab. |

| 20 Mins | Nano lab. |

Calibration of an opto-mechanical holeplate with an expanded uncertainty of 500 nm. The holeplate is a design from DTU used to verify industrial CMMs.

Scatterometry is used for quality control of an injection molded component of clear plastic. The visible colours result from the nanostructures in the component.

Tour 3: Novo Nordisk

Location: 3400 Brennum Park 20k, reception building 20k, Hillerød, DK

Date: Friday 16th June 2023

Time: 09:15 – 13:00

Novo Nordisk at a glance

Novo Nordisk is a leading global healthcare company, founded in 1923 and headquartered in Denmark. Our purpose is to drive change to defeat diabetes and other serious chronic diseases such as obesity and rare blood and endocrine disorders. We do so by pioneering scientific breakthroughs, expanding access to our medicines and working to prevent and ultimately cure disease.

Website: www.novonordisk.com

The visit will cover part of site Hillerød and follow the value chain of injection pens device components. The tour will include visit to three facilities.

- The visit at the moulding lab and toolshop demonstrates early design development and material testing activities.

- The visit to manufacturing development showcases low volume and early production and device circularity sustainability initiatives.

- The visit to the manufacturing site includes moulding production and the metrology lab used for ensuring highest level of quality.

Tour Terms & Conditions

- Delegates are required to bring an EU recognised ID document as proof of identity . ID will be asked in case of safety or security emergencies.

- Delegates will be required to walk between facilities. Please see tour programme below for further information.

- Delegates should ALWAYS stay with their group and with their guide

- Delegates should not touch anything without approval

- Photos of videos are NOT permitted

- In case of emergency delegates should follow the emergency signs

Tour Programme A map of the Hillerød site can be found here.

| Time | Programme |

| 09:15 – 09:30 | Welcome to Novo. Check in with you group and safety brief at 20K reception. |

| 09:30 – 10:15 | Group A visit DDS Moulding Lab Toolshop with Rasmus Knudsen Group B visit DMS Metrology LAB, Moulding & Pre-assembly with Lorenzo Carli |

| 10:15 – 10:20 | Meet at 20k reception and group swap (5 min walk) |

| 10:20 – 11:05 | Group B visit DDS Moulding Lab Toolshop with Rasmus Knudsen Group A visit DMS Metrology LAB, Moulding & Pre-assembly with Lorenzo Carli |

| 11:05 – 11:20 | Meet at 24a reception and walk to DMD 24k (15 min walk) |

| 11:20 – 11:40 | Group A visit DMD Moulding Pilot Operations with Dario Loaldi Group B visit DMD Device Sustainability with Iranga Pereira and Jacob Sandager |

| 11:40 – 12:00 | Group B visit DMD Moulding Pilot Operations with Dario Loaldi Group A visit DMD Device Sustainability with Iranga Pereira and Jacob Sandager |

| 12:00 – 12:15 | Meet at canteen (15 min walk) |

| 12:15 – 12:45 | Lunch offered by DMS |

| 12:45 – 13:00 | Farewell |

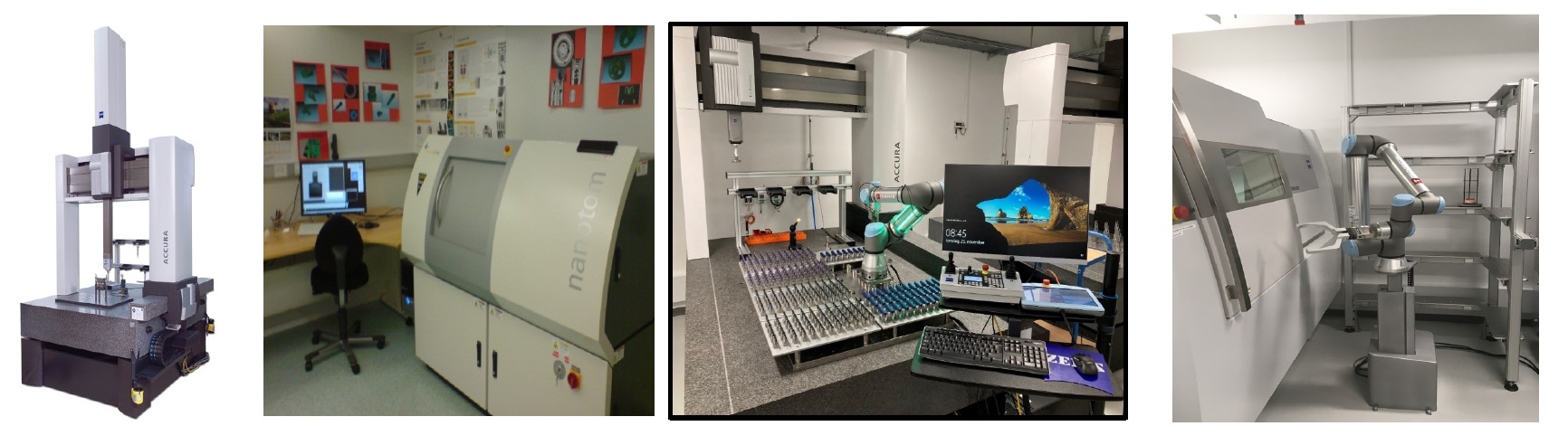

Metrology Lab at Novo Nordisk Hillerød (DK)

• Device R&D: 2 CT scan • Metrology Lab I (2011): 7 Zeiss CMM + 1 CT scanner (Zeiss M1500)

• Metrology Lab II (2018): 2 CMM + 1 CT (Zeiss M800)

• 14 employees performing dimensional and geometrical measurements

• 2 gluing robots, 2x 3D Printer (fixtures), 2 (+1) CMM robot, 1 CT robot

• Over 1400 measuring tasks in 2022. Forecast: ca. 15% more in 2023