Project Description

Thermal Issues

26 – 27 February 2020, Aachen, DE

Special Interest Group Meeting: Thermal Issues

Laboratory for Machine Tools and Production Engineering (WZL) of RWTH Aachen, and Fraunhofer Institute for Production Technology IPT, DE

26th – 27th February 2020

Thermal effects are regarded as a major contributor to errors on machine tools, on measuring equipment and on work pieces.

Measurement of thermal effects is becoming more important as work piece tolerances decrease, as thermal effects not only use a larger part of the tolerances, but also influence repeatability and long term stability of machine tools, and equipment.

As a consequence, several research groups and industries are working on simulation of thermal effects, in order to finally compensate thermally induced errors, or new help to develop concepts to reduce thermally induced errors.

The intensive on-going work in this area led us to bring together a further internationally-coordinated meeting and are seeking papers in the following categories:

1. Measurement of thermal influences in production equipment, process and product

- Understanding the machines thermal behaviour and the errors on the machined workpiece follows a deep understanding and evaluation of the thermal chain of causes and the error sources

- Equipment and methods for direct and indirect measurements

2. Modelling and model reduction techniques

- Modelling of temperature and deformation fields: lumped-mass, structural FE, CFD

- Reduction of multi-physics models, reducing complexity and size

- Thermal mode shapes (temperature and deformation): Eigen-modes, POD-modes, FRF-based modes

3. Compensation and correction of thermal effects (e.g. Artificial Intelligent algorithms and techniques)

- Reducing thermal errors of machines based on control theory

- Input data and sensor data processing, modelling techniques and actuator control

- Implementation in machine controls and manufacturing planning

4. Design principles for thermally robust production equipment (e.g. Machine Elements, Machine Structures)

- The enhancement of machine positioning based on high precision machine design principles. These aim to reduce either the generation of temperature gradients or the deformation sensitivity of the machine structure to them. (Characteristic examples of current research: Heat pipes, Phase-change materials, cooling systems, heat accumulators)

5. Testworkpieces and assessment

- Methods for evaluating thermal errors of machines by manufactured testworkpieces, design of testworkpieces, manufacturing strategies and evaluation approaches

6. Thermo-energetic design

- Design, correction or compensation measures that satisfy the conflicting goals of reducing energy consumption and increasing accuracy and productivity in machining

7. Temperature Measurement & Control

- Accurate and fast temperature measurement in scientific and industrial environment

- Control algorithms, thermal actuation

- Thermal system identical measurements (model measurements)

- Challenges under cryogenic conditions

The local hosts and organising committee supporting euspen for this Special Interest Group meeting on Thermal Issues are :- Dr. Theo A.M. Ruijl, MI-Partners Bv, NL; Dr. Josef Mayr, ETH Zurich, CH; Prof. Christian Brecher, WZL, DE and Prof. Steffen Ihlenfeldt, TU Dresden, DE and Fraunhofer IPT, DE

Key Dates:

18th December 2019: Online abstract submission deadline

24th January 2020: Notification of presentation (oral/poster)

24th January 2020: Programme available online

Registration Fees:

Fees and information about the Thermal Issues meeting. The published fees are inclusive of the networking dinner and company tours.

- €195.00+VAT euspen Student members

- €395.00+VAT euspen member

- €495.00+VAT Non-euspen members

- €595.00+VAT Exhibitor (table top)

- €45.00+VAT Networking Dinner

- Company Tour Included with Registration Fee

All speakers and presenters must register for the conference using the appropriate delegate fee.

Submit an abstract for Thermal Issues

We are delighted to bring together leading expertise globally to an open forum for

focused presentations and discussions on thermal issues.

Announcement & Call for Abstracts

Come and join your international peers and maintain a leading edge on technology, customers, partners and suppliers. Access the greatest minds in working within the field of thermal issues research and development. Share knowledge and information and stimulate debates.

Themes :-

- Measurement of thermal influences in production equipment, process and product

- Modelling and model reduction techniques

- Compensation and correction of thermal effects

- Design principles for thermally robust production equipment (e.g. Machine Elements, Machine Structures)

- Test workpieces and assessment

- Thermo-energetic design

- Temperature Measurement & Control

Submission of abstracts

Abstracts are expected to describe original work, previously unpublished and should indicate new and significant advances and their importance. For this meeting the number of pages per abstract is flexible between half a page and up to four A4 pages long. You should use the links above to submit your abstract.

Following review of all abstracts authors will be notified of their presentation mode (poster/oral). The final decision on acceptance of all papers is made by the Editor and Scientific Committee of the SIG meeting.

The invitation to submit an abstract does not constitute an offer to pay travel, accommodation or registration costs associated with the conference. Similarly, no speaker fee is paid to successful participants. All speakers must register for the conference and transfer registration fee. In specific cases the organising committee reserves the right to deviate from the standard procedure.

Keynotes

Professor Christian Brecher

WZL – Laboratory for Machine Tools and Production Engineering, RWTH University, Aachen

Thermo-Energetic Design of Machine Tools – A systematic approach to solve the conflict between power efficiency, accuracy and productivity

The challenge of research in the CRC/TR96 derives from the attempt to satisfy the conflicting goals of reducing energy consumption and increasing accuracy and productivity in machining. The solution approach pursued is based on measures that make it possible to guarantee process accuracy despite increasing power losses without additional energetic measures under thermal transient environmental conditions and under operating conditions characterised by individual and small series production. The scientists of the CRC/TR 96 are researching and developing effective correction and compensation solutions for the thermo-elastic machine behaviour during the course of the project, which will enable precision machining under the future conditions of energy-efficient production. In the 3rd funding phase, the CRC/TR 96 focuses on the application of the developed solutions on the entire machine under the conditions of real operation. This leads to new scientific challenges due to a multitude of uncertainties and parameter fluctuations. The models have to be further developed and new solutions for the control of variable operating conditions such as online identification have to be developed.

Professor Christian Brecher, born 25 August1969, was a research associate and senior engineer in the Machine Technology Department at the Laboratory for Machine Tools and Production Engineering (WZL) of the RWTH University in Aachen from 1995 till 2001 and earned his doctorate at the Faculty of Mechanical Engineering there. Some three years into a career in the mechanical engineering industry, he was appointed University Professor of Mechanical Engineering at the RWTH University in Aachen and Member of the Board of Directors of the WZL and IPT (Fraunhofer Institute for Production Technology). His areas of specialist expertise include machine, transmission and control systems technology. In 2012 Professor Brecher additionally became a founding member along with Professor Hopmann of the Aachen Centre for Integrative Lightweight Engineering at the RWTH University in Aachen. From 2015 to 2017 Professor Brecher became the acting Head of Institute at the Fraunhofer Institute for Production Technology IPT and in January 2018 he accepted the permanent position of Head of Institute.

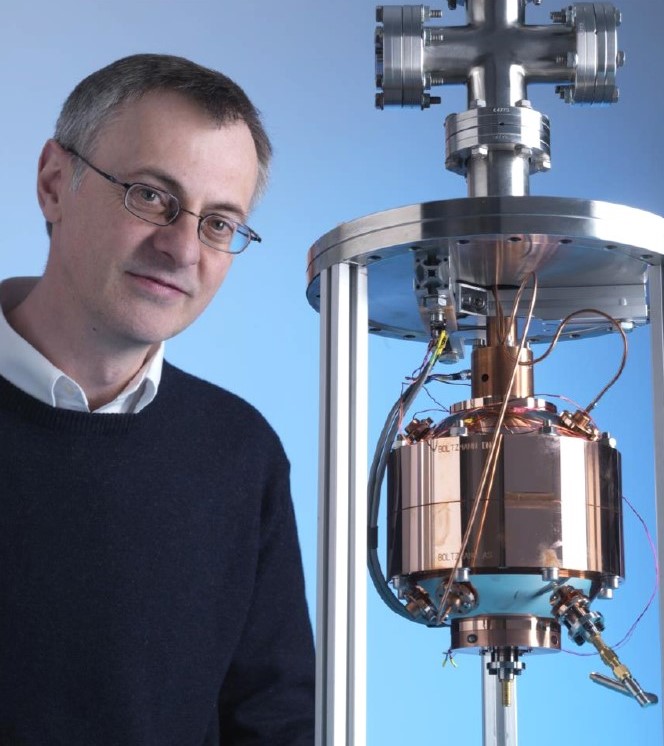

Graham Machin with NPL’s acoustic thermometer

Professor Graham Machin, FREng

Head of Temperature Standards, NPL Fellow

National Physical Laboratory

UK Immediate Past President Institute of Measurement and Control

The implications of the kelvin redefinition

In November 2018 the General Conference of Weights and Measures (CGPM) made history by agreeing to redefine the international system of units (the SI) in terms of a defined set of fundamental constants. The kelvin from that time on was defined in terms of a fixed value of the Boltzmann constant. Starting from the previous definition of the kelvin, based on the triple point of water, this talk will explain how the kelvin was redefined including; the wording of the redefinition, the co-ordinated effort in determining low uncertainty values of the Boltzmann constant for the redefinition, and, the extensive preparations undertaken for introducing the mise en pratique for the definition of the kelvin (MeP-K-19) which will regulate the realisation and dissemination of the kelvin from the date of its redefinition. As the international thermometry community transitions to realisating and disseminating the redefined kelvin the short, medium and long term implications that the redefinition will have for the disciple of thermometry will be discussed.

Professor Graham Machin FREng, BSc (Hons), DPhil (Oxon), DSc, CPhys, CEng, FInstP, FInstMC GM is the science leader of the NPL Temperature and Humidity Group and an NPL Fellow. He has more than 30 years’ experience in thermometry research, published more than 220 technical papers and given numerous invited/keynote addresses. He is visiting Professor of Clinical Thermal Imaging (University of South Wales) and Distinguished Visiting Fellow (University of Valladolid, Spain). He represents the UK on the Consultative Committee of Thermometry (CCT) and IMEKO TC12, chairs the CCT working group for Noncontact thermometry and is an international invited expert on the CAS “very low temperature thermometry” project (2017-2022). He was President of the UK Institute of Measurement and Control (2018-2019), chair of the Euramet Technical Committee for Thermometry from (2014-2018) and served on the EPSRC Physical Sciences Strategic Advisory Team (2014-2017). GM was awarded the Institute of Measurement and Control (InstMC) Callendar medal in 2012 for “outstanding contributions to the art of temperature measurement”, Honorary Scientist of the Chinese Academy of Sciences (CAS) (2019) and elected Fellow of the Royal Academy of Engineering (2019). Current research interests are primary thermometry (acoustic, radiometric and especially all aspects of realising the redefined kelvin), radiation thermometry and thermal imaging, new thermocouples, sensor self-validation methods, reliable clinical thermometry (contact, non-contact and internal), reliable temperature (and other) measurements in hostile environments (especially aerospace and nuclear decommissioning).

He is project director of the “Realising the redefined kelvin” (Sep 2019) for EURAMET, a founder member of the “Body Temperature Initiative” which aims to improve clinical thermometry throughout the NHS and leads NPL’s metrology activity in nuclear decommissioning.